同达(泰兴)机械科技有限公司

TONGDA CHINA MACHINERY TECHNOLOGY CO., LTD.

Call Us Today

+86-138-5288-0212

Send Us

No. 28, Jiangping North Road, Taixing City, Jiangsu Province

| Availability: | |

|---|---|

| Quantity: | |

100ml-5L Automatic Extrusion Blow Molding Machine (Single & Double Station)

TD-YD Series

Technical Specificatio

Model | Unite | TD-YD60 | TD-YD60II |

Station | Single | Double | |

Max. Product Volume | Liter | 3 | 2 |

Dry Cycle | PC/H | 1100 | 950*2 |

Output of HDPE | Kg/h | 75 | 75 |

Weight of machine | Ton | 5 | 6 |

Size of machine(L*W*H) | mm | 3.4*1.8*2.2 | 3.4*1.8*2.2 |

Max.die diameter | mm | 80 | 80 |

Die head heating zone | Pcs | 3 | 3 |

Die head heating | Kw | 7 | 7 |

Platen distance | mm | 138-400 | 138-400 |

Template size | mm | 300*300 | 300*300 |

Max,size of mold | mm | 290*320 | 290*320 |

Mold moving stroke | mm | 380 | 380 |

Clamping force | Kn | 50 | 50 |

Screw diameter | mm | 60 | 60 |

Screw heating power | Kw | 11.2 | 11.2 |

Oil pump motor power | Kw | 7.5 | 7.5 |

Screw motor power | Kw | 15 | 15 |

Total power | Kw | 40.7 | 40.7 |

Blow pressure | Mpa | 0.6 | 0.6 |

Air consumption | m³/min | 0.4 | 0.4 |

Cooling water pressure | Mpa | 0.3 | 0.3 |

Water consumption | L/min | 40 | 60 |

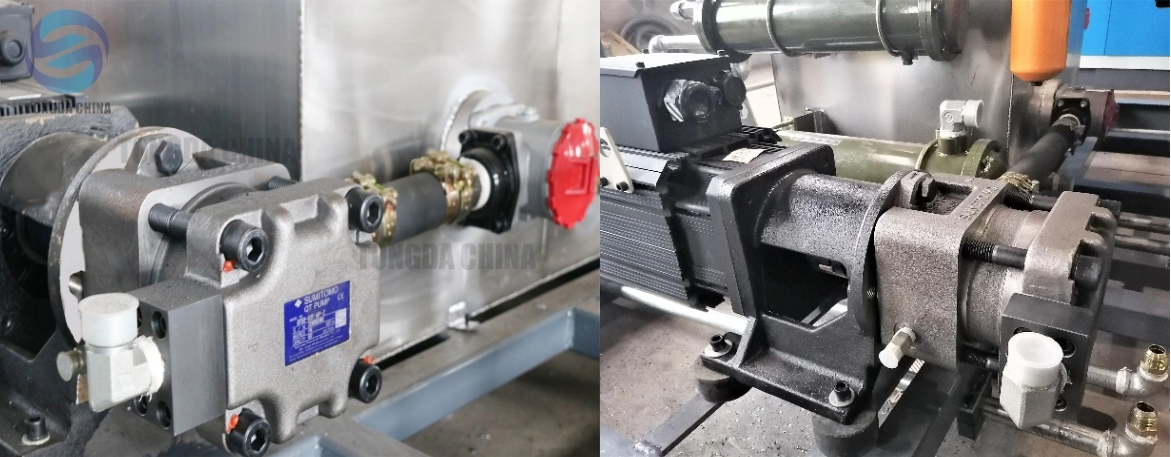

Servo system : optional hydraulic servo system, save more than 30% electrical energy, meeting with oil pump from America or Japan

Hydraulic system: it is controlled by proportional pressure and is provided with Yuken hydraulic components, so it is consistent and reliable

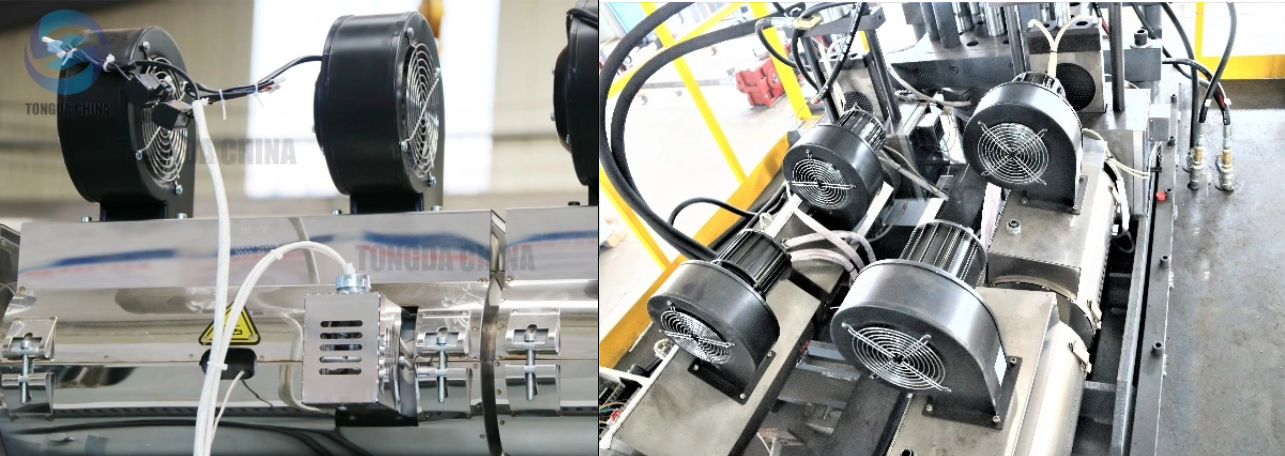

Plasticization system: efficient plasticization twin-screw ensures sufficient and even plasticization , The temperature control of the ceramic heater is stable and efficient, and it saves energy by 30%-40%

Speed regulating system : frequency variable regulating and alloy steel hard finishing reducer steadily regulate speed with low noise, so they are endurable.

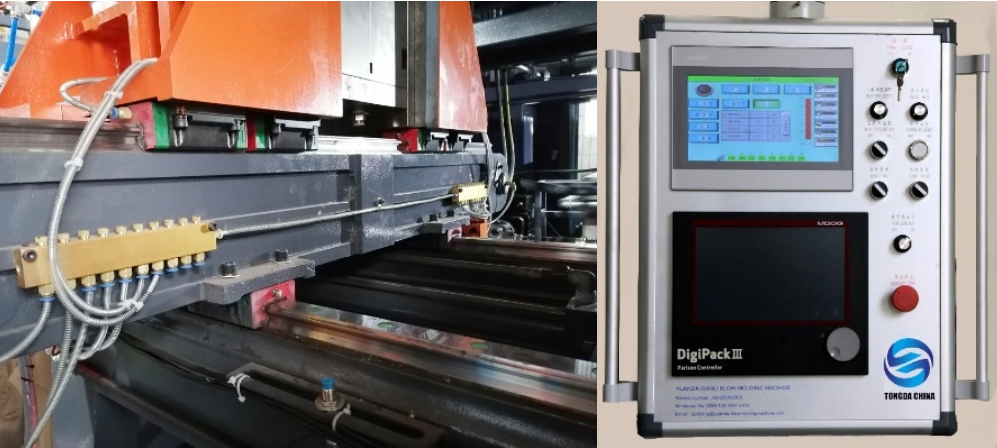

Clamping system and die shifting system: dia shifting and clamping are done by camping mechanism with double straight line trail, so it has high accuracy , low resistance and high speed.

Optional Machine Accessibility

Automatic lubrication of moving parts Moog parasion wall thickness controller

Fully automatic production and conveying line with Robot

Application:

Lubricating Oil

Daily Necessities

Chemical Industry

Food

Amusement Devices

Automobile

Transport Facilitiese

Others