同达(泰兴)机械科技有限公司

TONGDA CHINA MACHINERY TECHNOLOGY CO., LTD.

Call Us Today

+86-138-5288-0212

Send Us

No. 28, Jiangping North Road, Taixing City, Jiangsu Province

| Availability: | |

|---|---|

| Quantity: | |

25L-30L 30L-60L accumulator head type Automatic Extrusion Blow Molding Machine (Single Station)

TD-YD Series

Technical Specification

Model | Unite | TD-YD90 | TD-YD100II |

Station | Single | Double | |

Max. Product Volume | Liter | 15 | 15 |

Dry Cycle | PC/H | 700 | 700*2 |

Output of HDPE | Kg/h | 160 | 230 |

Weight of machine | Ton | 18 | 20 |

Size of machine(L*W*H) | mm | 6.1*4.2*3.3 | 6.8*5.5*3.3 |

Max.die diameter | mm | 200 | 240 |

Die head heating zone | Pcs | 3 | 3 |

Die head heating | Kw | 9.1 | 9.1 |

Platen distance | mm | 350-800 | 420-900 |

Template size | mm | 580*540 | 650*650 |

Max,size of mold | mm | 730*540 | 740*650 |

Mold moving stroke | mm | 750 | 750 |

Clamping force | Kn | 160 | 160 |

Screw diameter | mm | 90 | 100 |

Screw heating power | Kw | 26 | 26 |

Oil pump motor power | Kw | 22 | 25 |

Screw motor power | Kw | 30 | 50(6class) |

Total power | Kw | 78 | 101 |

Blow pressure | Mpa | 0.6 | 0.6 |

Air consumption | m³/min | 0.4 | 0.4 |

Cooling water pressure | Mpa | 0.3 | 0.3 |

Water consumption | L/min | 60 | 100 |

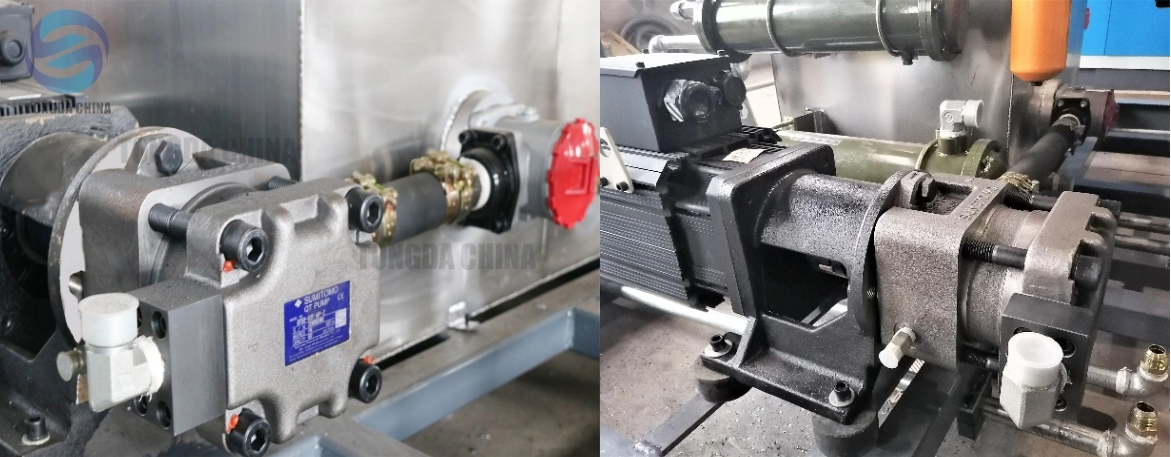

Servo system : optional hydraulic servo system, save more than 30% electrical energy, meeting with oil pump from America or Japan

Hydraulic system: it is controlled by proportional pressure and is provided with Yuken hydraulic components, so it is consistent and reliable

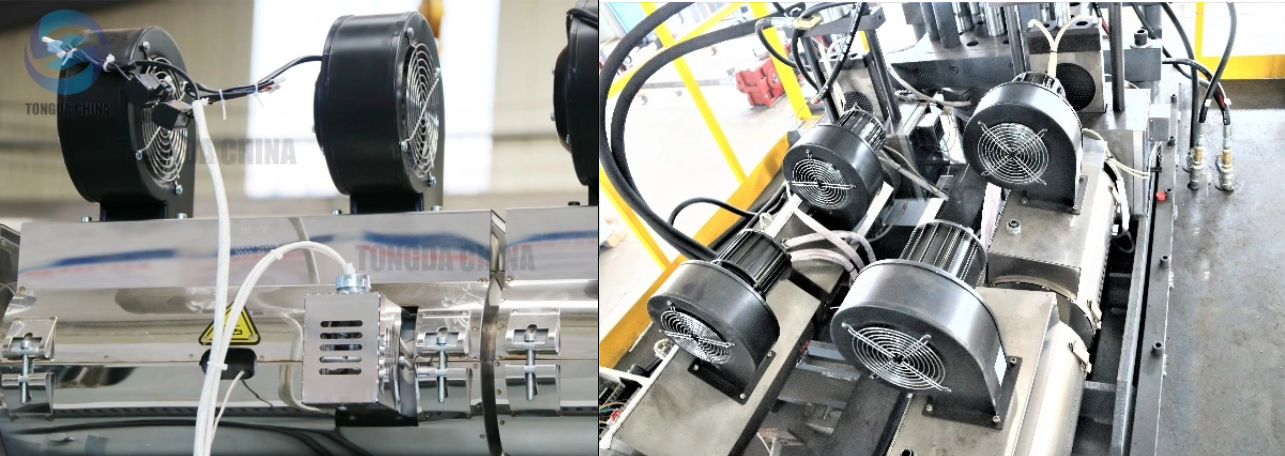

Plasticization system: efficient plasticization twin-screw ensures sufficient and even plasticization , The temperature control of the ceramic heater is stable and efficient, and it saves energy by 30%-40%

Speed regulating system : frequency variable regulating and alloy steel hard finishing reducer steadily regulate speed with low noise, so they are endurable.

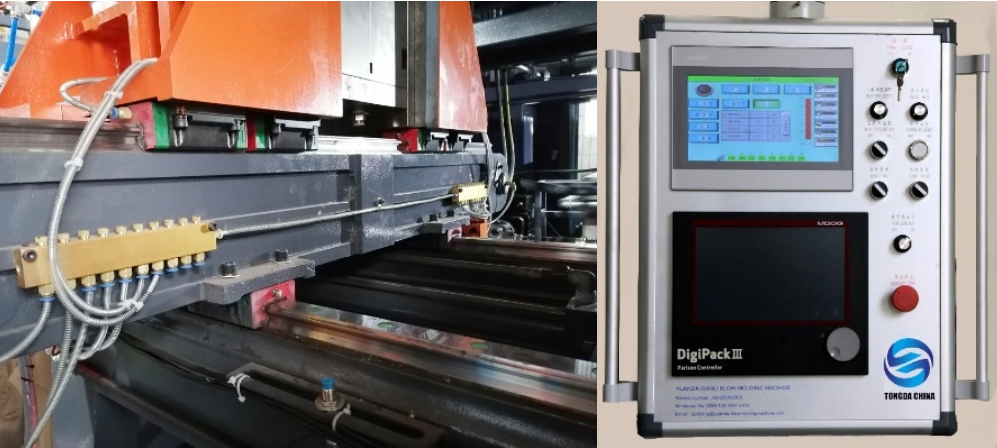

Clamping system and die shifting system: dia shifting and clamping are done by camping mechanism with double straight line trail, so it has high accuracy , low resistance and high speed.

Optional Machine Accessibility

Automatic lubrication of moving parts Moog parasion wall thickness controller

Fully automatic production and conveying line with Robot

Lubricating Oil

Daily Necessities

Chemical Industry

Food

Amusement Devices

Automobile

Transport Facilitiese

Others